1. Cost Comparison

The cost comparison shows a 27.3% difference in CAPEX and a 39.4% difference in OPEX between a conventional data center with traditional operating practices and a prefabricated modular data center designed and implemented using industry best practices.

2. Conventional Construction

When a data center is designed using the traditional model, it must be deployed with its full final capacity from the start. Designers plan for the worst-case end-state load because the costs and operational penalties of running out of capacity during the data center’s lifespan are extremely high. In reality, the final load rarely reaches the projected value. Significant savings in both CAPEX and OPEX can be achieved when the data center is built to grow modularly, deployed in phases according to demand.

3. Modularity and Scalability

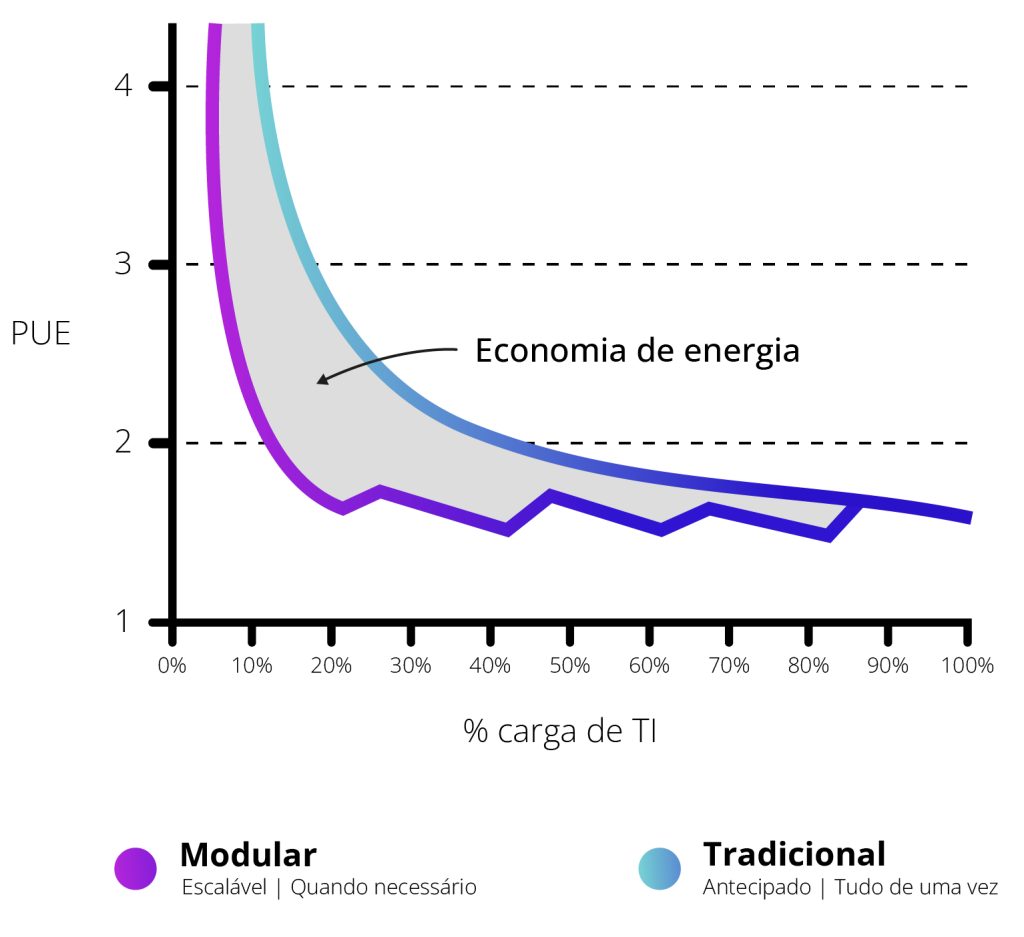

Being able to deploy a data center in modules and scale its infrastructure over time leads to greater savings, because capital costs and maintenance costs are deferred until they are truly needed to support the load. Additionally, the system operates closer to its actual demand at each phase, resulting in energy savings. As shown, there is a considerable reduction in OPEX.

5. Climatization, Power Distribution, Raised Floor

The cooling systems in modular data centers are more efficient, as they use economizer-based models and are positioned closer to the loads. This reduces energy costs because it greatly improves air distribution efficiency. Power distribution is also more efficient since the UPS units are located near the loads, and raised floor costs can be avoided when cooling is done in row or in rack, with power and cabling routed overhead.

6. Prefabricated

This standardized prefabricated architecture reduces CAPEX primarily because components are assembled and integrated by a single provider. Secondly, factory assembly is less expensive than on-site construction, which requires an extensive management structure to coordinate multiple field vendors. In addition, the time spent tuning the cooling system controls—integrating fans, pumps, circuits, chillers, cooling towers, and more—is drastically reduced when standard modules are deployed.

7. Smaller Areas

Traditional buildings are designed with people in mind. For that reason, electrical and/or mechanical rooms inside a building may be specified to consume 4 to 5 times the floor space to meet local code requirements, compared to modular solutions designed for infrequent human interaction. This extra space then requires more energy and more water to cool, heat, and ventilate. The compact nature of a pre-engineered, prefabricated modular solution means more equipment is packed into a single “enclosure,” resulting in higher efficiency when considering footprint. With a typical cost of $1,076 to $1,614 per square meter, this leads to significant savings. The confined footprint inside the modular solution also allows operations to be tightly controlled, as the influence of other systems (such as building comfort HVAC) is nonexistent. This helps prevent overcooling. Additionally, prefabricated facility modules are free from “parasitic” loads such as office areas or shared lighting.

8. Standardized and Integrated Cooling Controls

Cooling controls directly affect the performance of the cooling plant and its ability to operate in economizer mode. A design with standardized integrated controls makes cooling plant operations more predictable and reliable. Traditional cooling components are often oversized to account for performance uncertainty resulting from one-off systems with custom controls.

Traditional designs almost always intentionally incorporate excess load capacity, since expanding power capacity is extremely difficult and expensive in a live data center. This often leads to an overly conservative approach to capacity planning, resulting in higher upfront capital costs and a chronically inefficient data center.

Prefabricated modular data centers, on the other hand, eliminate this tendency toward unnecessary oversizing, as their modular and standardized architecture makes it much easier to add or reduce capacity to meet dynamic, real-world demand. Combined with integrated and efficient power and cooling technologies, this leads to approximately 30% savings in Total Cost of Ownership (TCO | Total Cost of Ownership) compared to traditional data centers.